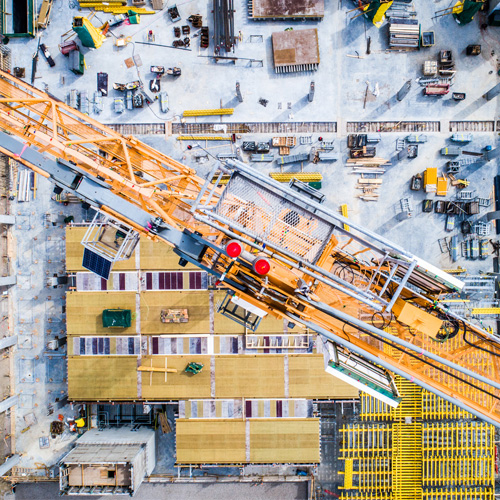

What Daily Process Improvement Looks Like in Construction

Process Improvement is at its best when it doesn’t look like much. We often fall into the trap of needing expensive equipment or consultants to save money, and in the end it costs us money.

Process Improvement is at its best when it doesn’t look like much. We often fall into the trap of needing expensive equipment or consultants to save money, and in the end it costs us money.

Rule of thumb: real change needs to develop from inside. If you try to force it from the outside, it will be short-lived and expensive.

In Construction, you’re managing multiple remote sites, operating on different projects and under unique circumstances. Change needs to occur uniformly within the company’s culture; if your foreman and crews don’t buy in, things will simply revert back to the way it used to be as soon as you’re not around.

Change that makes real money has 2 overlapping qualities: it’s about leadership (it starts with you, not them), and it’s about culture (buy-in required, which leads to consistency). Time is money, and in the construction industry, a shared enthusiasm for always finding more efficient ways to complete projects lays the groundwork for daily process improvement.

Leadership

Don’t tell your troops to leap out of the trench while you finish your power lunch. Go to the job sites and and ask what bugs them. Have those conversations that we always think we don’t have time for.

Your crew is paying attention to their environment and their cohorts differently than you are. If the port-a-potty is too far away and the cinder blocks, which no one has used for weeks, are too close, then your team will catch the inefficiency long before you do. If someone doesn’t have the training they need, your team is the most likely to spot it before a dangerous accident. Trust that your foremen and crews have a perspective that you don’t, and create opportunities and incentives for them to offer solutions where they see problems.

If it gets the job done faster, your crews will embrace the “lean way.” You’ll drive the initiative and your team will respond admirably because they see the wins. But, these changes will evaporate in 4 months if you put the autopilot on now.

Systemic change is a commitment. It’s:

Good leadership is about fostering a healthy sense of urgency. Unhealthy urgency is unsustainable and corner-office-driven. You need urgency that comes from the work site and sustains itself month after month, year after year.

It’s not enough to keep the machinery well oiled for a month. There’s a sense of urgency – akin to a project deadline that never goes away – that needs to stay consistent day in and day out.

Culture

“Empowering” is a great word for a PowerPoint or a pep talk, but what we need is follow through. That looks like 4 things:

Together, your company is building more than infrastructure. You’re building a company culture, and all of the standards that go along with it. Make consistent process improvement a part of your corporate ethos and you’ll immediately notice the positive impact to employee morale, productivity, and your bottom line.

“Processes underpin business capabilities, and capabilities underpin strategy execution.”

— Pearl Zhu

This sounds self-explanatory, and it largely is, but it can also fall through the cracks when you’re rushing through setup time, trying to get started.

This sounds self-explanatory, and it largely is, but it can also fall through the cracks when you’re rushing through setup time, trying to get started.