What Daily Process Improvement Looks Like in Professional Services

Process Improvement is at its best when it doesn’t look like much. We often fall into the trap of needing expensive equipment or consultants to save money and, in the end, it costs us money.

Process Improvement is at its best when it doesn’t look like much. We often fall into the trap of needing expensive equipment or consultants to save money and, in the end, it costs us money.

Rule of thumb: real change needs to develop from inside. If you try to force it from the outside, it will be short-lived – and expensive.

In Professional Services, improving efficiency usually means increasing turn around times (whether that’s a file for a lawyer or a patient for a clinic) without sacrificing attention to detail. Spoiler alert: if it feels easy to start, you’re doing it wrong.

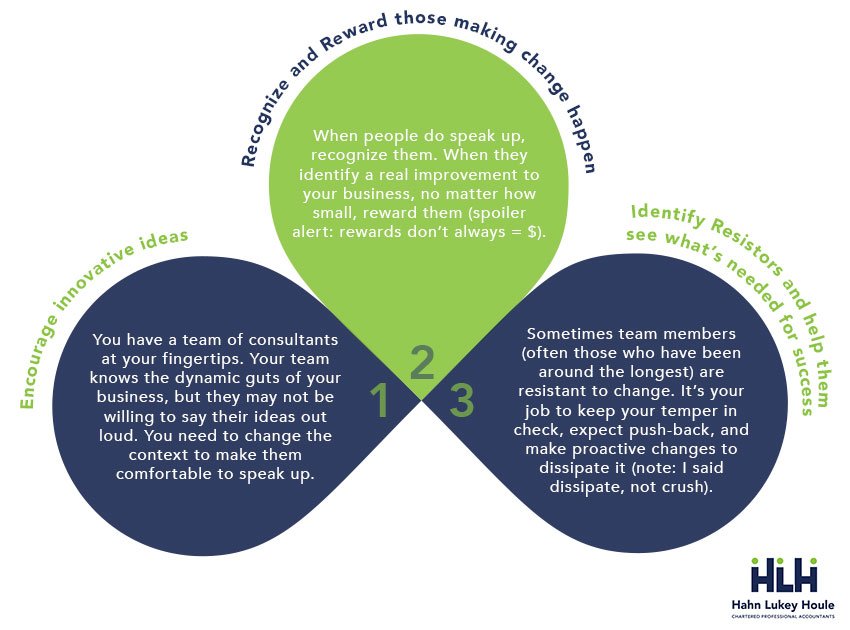

Changes that make real money have 3 overlapping qualities: they’re about leadership (it starts with you, not them), problem-solving (as in, they must address the root source of inefficiencies that already exist within the organization), and culture (the buy-in required, which leads to consistency).

Case in Point

Let’s imagine a busy dental clinic as our case study. The waiting room is chaotic, patients are waiting long periods for their appointments to start, and dental hygienists are feeling rushed as frantic receptionists react to impatient clients. The practice owner hears complaints from staff that they’re under enormous stress.

The first thing the owner does is hire a consultant. The consultant hears the words “busy”, “chaotic”, and “disorganized” from the practice owner, and walks into the clinic. He assesses that the software the receptionists are using is outdated and recommends a more powerful software tool. The software is exorbitantly expensive, but the consultant assures the practice owner that it will answer all their problems.

But does it? Not necessarily. The receptionists struggle to re-learn their jobs as they adjust to the new software. Patients continue to wait, as the receptionists struggle to navigate the program. Dental hygienists are still rushing, as the extended check-in time cuts into their appointment blocks. Staff are more distressed than ever. How could this investment be putting the clinic further in the hole, and not further ahead?

The practice owner started from the wrong place. Consider the qualities of effective process improvement for your team, and how they could have changed the outcome at the clinic:

Leadership

You have a well-educated, professional team who trained for years to get into your office and make it work. You don’t need to make process improvement an edict. They want to help, just let them.

Catch 10 people at their desks (when they aren’t fighting deadlines) and ask them what bugs them. They probably have answers to that question and have been waiting to be asked. Have those conversations that we always think we don’t have time for.

Authentically support your team and they’ll embrace process improvements. That brings in the next hurdle; that change will evaporate in 4 months if you put the autopilot on.

Systemic change is a commitment. It’s:

Good leadership is about fostering a healthy sense of urgency. Unhealthy urgency is unsustainable and corner-office-driven. You need urgency from lunchrooms, cubicles, and front desks.

Problem-Solving

The problems of one department are often connected to the problems of another. Sometimes, those issues originate from a lack of clarity from the top. Get to the bottom of the barriers holding your team back by:

- Mapping out the challenges across the organization: As leaders, we can never look at our teams’ issues in a vacuum. It can be helpful to create a visual ‘org chart’ and list the struggles under each department. Then, we can take a step back and truly see where issues originate and how they intersect.

- Finding out what’s getting in the way, and changing it: Your team can’t do the job without the right tools. Whether breaking down departmental silos, training for more skills, or reorganizing your management structure, you need to make it happen for your strategic culture to take root.

- Document, document, document! It’s great to experience that “aha!” moment in a staff meeting and verbally agree to a new process. But time goes on, people leave, and new people replace them. Processes that aren’t documented – and accessible! – are the dormant problems of the future.

Culture

“Empowerment” is a great word to include in a PowerPoint, but we need more than lip service. We need follow-through. You can create cultural shifts 3 ways:

Let’s visit our dental office in a parallel universe. In this universe, the practice owner started by speaking to staff and explaining his vision of a calm, efficient clinic. He listened to their problems, asked questions, and took notes. He stepped back and realized that the triage process for new patients was being done verbally, tying up staff unnecessarily. The receptionists documented their triage process, which became a form for patients to fill out upon arrival. By encouraging all of this, he also set a precedent for everyone to think differently about their impact within the workplace.

In its most effective form, process improvement is the path of least resistance, even if it has a few overgrown weeds in the way. It’s up to us to clear the lines of communication and help our teams move forward.

“For companies to change, we need to stop thinking like mechanics and to start acting like gardeners.”

— Alan M. Webber